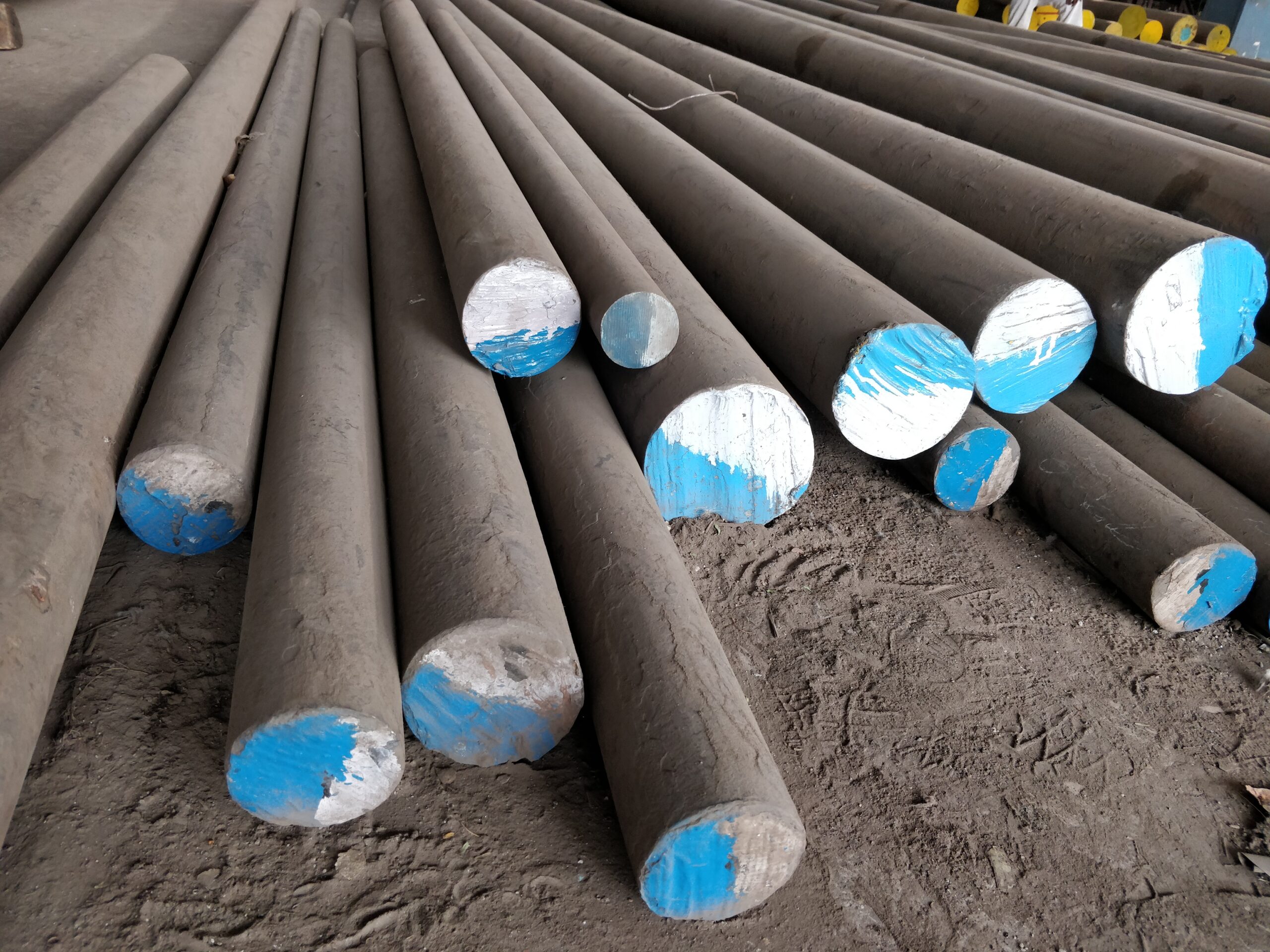

EN47 / 50CrV4/ 51CrV4/ AISI 6150 Spring Steel

EN47 is suitable for oil hardening and tempering. When used in the oil hardened and tempered condition EN47 spring steel combines spring characteristics with good wear and abrasion resistance. When hardened EN47 offers excellent toughness and shock resistance which make it a suitable alloy spring steel for parts exposed to stress, shock and vibration.

Applications

EN47 is used widely in the motor vehicle industry and many general engineering applications. Suitable for applications that require high tensile strength and toughness. Typical applications include crankshafts, steering knuckles, gears, spindles and pumps.

Forging

Preheat the steel carefully, then raise temperature to 1050°C for forging. Do not forge below 840°C. After forging EN47 spring steel cool slowly, preferably in a furnace.

Annealing

Heat slowly to 820-840°C, soak well. Cool slowly in the furnace.

Hardening

Heat slowly to 650-700°C and thoroughly soak. Continue to heat the steel to the final hardening temperature of 830-860°C and allow the component to be heated through. Quench in oil.

Tempering

Temper the EN47 spring steel component immediately after quenching whilst tools are still hand warm. Re-heat to the tempering temperature then soak for one hour per 25 millimetre of total thickness (2 hours minimum) Cool in air. For most applications tempering of this grade will be between 400-600°C.

Welding

We recommend you contact your welding consumables supplier who should provide you full assistance and information on welding EN47 chrome vanadium spring steel.

EN 47 SPRING STEEL ALLOYRA